Design defects are all too common in construction, and although some defects can be minor, others can have significant flow-on effects resulting in costly redesigns and fixes.

At ProFinish, our team assess all structural and architectural drawings, reviewing the fire resistance levels (FRLs) required and ensuring they are to code and best practice before recommending passive fire protection solutions. Too often we see this costly oversight – unprotected steel members connecting or interacting with a primary protected steel member.

Design Defect: Unprotected Structural Steel Members

Steel is a thermally high conductive material and rapidly loses strength when left unprotected and exposed to fire. Some of the most critical components of a structure are joints and connections and they must be properly protected from fire to prevent premature collapse. In many of the architectural and structural drawings our team reviewed, joints, connections and secondary members are interacting with a protected primary member without an FRL applied.

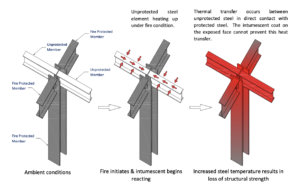

Where unprotected steel members are connected to protected steel members a local hot spot is likely to occur and decrease the FRL rating of the protected primary member. This is depicted in the figure below.

Figure 1. Unprotected steel in contact with protected steel.[1]

Common Examples of Unprotected Secondary Members

One of the most common areas we see this design defect is around windows. Primary structural steel columns have the correct FRL and clearances applied, but window headers will not have an FRL applied. In this instance, the architect will not allow the clearances required to apply passive fire protection to these members in the design.

When this plan is sent for passive fire protection specification this design defect will be realised and the window and surrounding area will need to be redesigned with a 500mm clearance to the window header, altering the architect’s exterior and interior design and vision with a severe knock-on effect.

If this design defect is realised and corrected once construction has already commenced, or even in the later stages of design, it can carry significant costs and delays for the project.

Industry Guidelines: Fire Protection

Australian Standards (AS4100 Cl12.10.1) requires connections to be fire protected with the maximum thickness of fire protection material needed by the primary members [2]. But there is no current code of practice or specifications when it comes to the interaction of primary and secondary steel members, which is why we see it left unspecified in so many cases.

Research and Testing

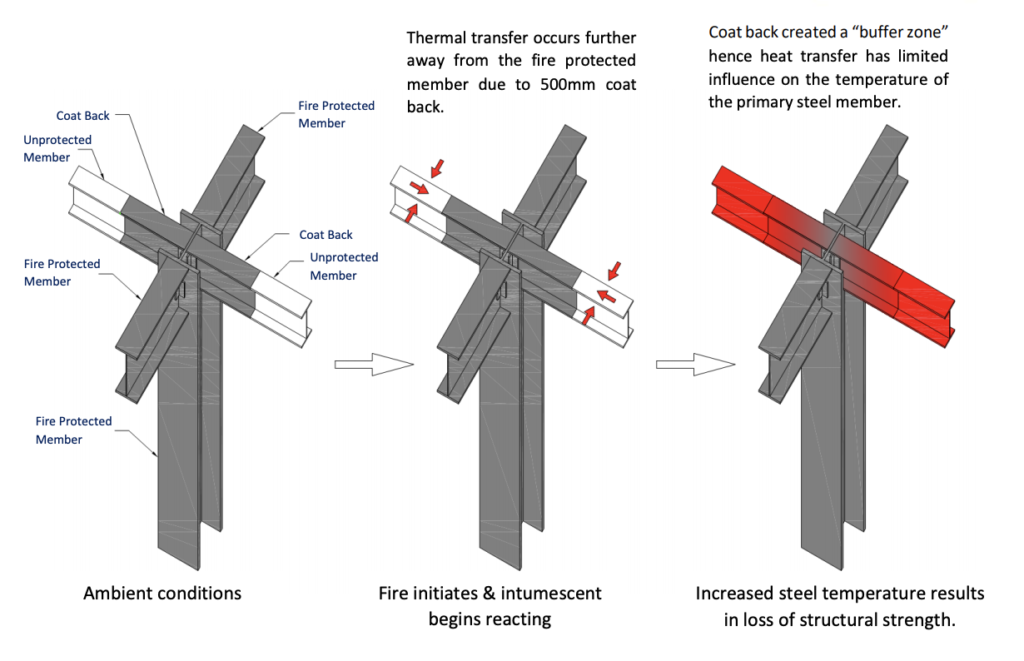

Research and testing have been carried out on the effects of using a ‘coat back’ (see Figure 2) solution to protect the connections and interactions of primary and secondary steel members by multiple industry bodies, manufacturers and institutions.

The Steel Construction Institute (SCI) has published detailed technical data after testing various coat back lengths with non-reactive passive fire protection materials such as vermiculite and board protects. The conclusion being that the New Zealand Heavy Engineering Research Association (HERA) recommendation of a 300mm coat back length is sufficient to allow for variations to FRLs and the relative sizes of the steel members [3].

Figure 2. 500mm coat back onto unprotected steel members.[1]

Studies into the required coat back lengths for steel protected by intumescent coatings have also been conducted with technical guidance being generated by the Association of Specialist Fire Protection (ASFP) in regards to a coat back’ solution using intumescent products:

“The potential for heat transfer from unprotected structural steel into protected structural steel must be considered. It is normally considered good practice to protect the adjoining 500mm of ‘unprotected’ steel to limit unwanted heat transfer”. [4]

ProFinish Recommendations

When it comes to passive fire protection, architects and fire engineers should be working closely together to ensure the design of the building supports the specifications and requirements to guarantee the structural integrity and safety of the building. As a rule of thumb, an FRL and specification of a coat back of at least 300mm should be applied to all connections and interactions of primary and secondary steel members.

If you are preparing to, or are in the process of drafting specifications, (or have commenced a project), we strongly encourage you to involve the specialist team at ProFinish who can guide you through the process and help eliminate any design defects.

Contact the team by email, via our website or call (03) 5274 1226

References

[1] Figure 1 & 2, Nulifire SC902 Technical Advisory Note

[2] Standards Australia, AS4100-1998 Steel Structures, NSW: Standards Australia, 1998.

[3] New Zealand Heavy Engineering Research Association (HERA), (1998). Steel Design and Construction Bulletin, No 42, April 2008, Manukau City, New Zealand.

[4] Association for Specialist Fire Protection, TGD 8- Code of practice for junctions between different fire protection systems when applied to load-bearing structural steel elements., Association for Specialist Fire Protection, 2010.